In the construction of waterproofing projects, a small object that is inconspicuous but can play a greater role-non-woven fabric is often used. Why use non-woven fabrics? How to use it?

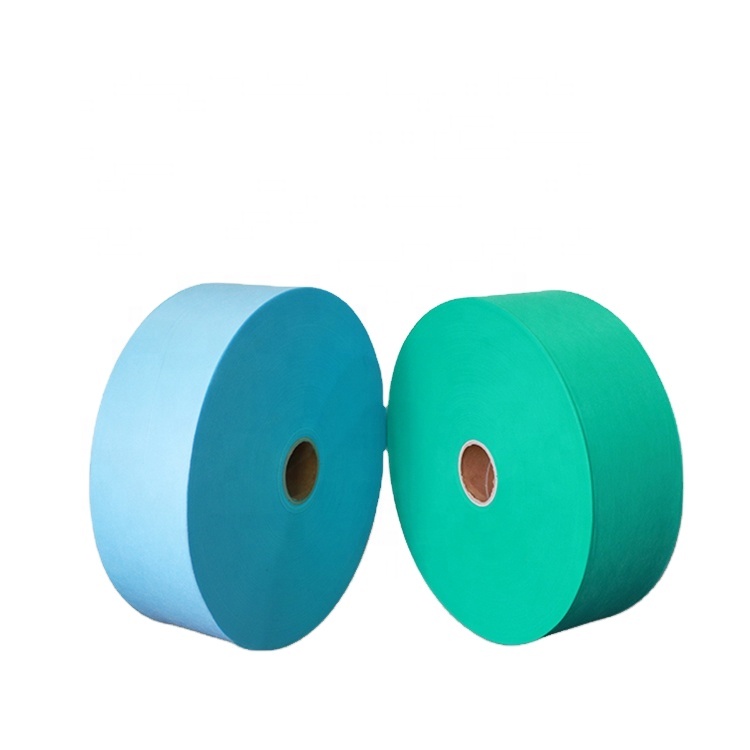

Non-woven fabrics, also called nonwoven fabrics, needle-punched cotton, etc., are composed of oriented or random fibers. It is called cloth because of its appearance and certain properties. It has the characteristics of moisture-proof, breathable, flexible, light weight, non-combustible, easy to decompose, non-toxic and non-irritating, rich in color, low price, and recyclable.

What is the effect of waterproof coating and non-woven fabric?

1. Because of its moisture resistance, breathability and sensitivity, non-woven fabrics can be closely combined with waterproof coatings. The more important effect of non-woven fabrics on waterproofing is-strengthening effect, anti-cracking, and in the root, Yin and Yang angles, The gutter and other detailed nodes can prevent leakage caused by the damage of the coating film when deformation and cracks occur due to settlement and structural temperature deformation.

2. Spreading a large area of non-woven fabric can not only enhance the tensile strength of the waterproof coating, on the other hand, it can also improve the uniformity of the thickness of the waterproof coating. When the waterproof layer is constructed on a large area, the selected waterproof coating must not be sprayed at one time. When the specified thickness is applied at one time, the coating film shrinks and the water evaporates, which is prone to cracks. The correct waterproof coating should be sprayed in layers. After the first coating is dried and formed into a film, the latter coating can be applied. The waterproof coating must reach the specified thickness, otherwise the carcass impregnation problem will occur.

3. Prevent the film from falling. When the waterproof coating is applied to the road and bridge deck on a steep slope, the coating will naturally flow down. With a non-woven fabric, it will adhere to a part of the coating to prevent it from flowing everywhere, which also increases the resistance of the coating when it flows downward. The carcass reinforcement material is added with a layer on the coating with long curing time and low viscosity, which can better ensure the construction quality of the coating film.

–Written by Amber

Post time: Dec-02-2021