The difference between coating non-woven fabric and film and non-woven fabric, coating non-woven fabric and film and non-woven fabric are both developed to make non-woven fabrics have a waterproof effect. Due to the different production processes, the final effects are also different.

First of all, the coated non-woven fabric is made by using equipment to melt the plastic and then spraying it on the surface of the non-woven fabric. The advantage is that the production speed is fast and the cost is low. The film-coated non-woven fabric is produced by compounding the already produced pe film and non-woven fabric in high-temperature equipment. The thickness of the two materials can be determined by the raw materials.

Secondly, look from the color. Since the coated non-woven fabric is formed by the film and the non-woven fabric at one time, the product produced has obvious small pits from the surface. The film non-woven fabric is a finished composite, and its smoothness and color are better than those of the coated non-woven fabric.

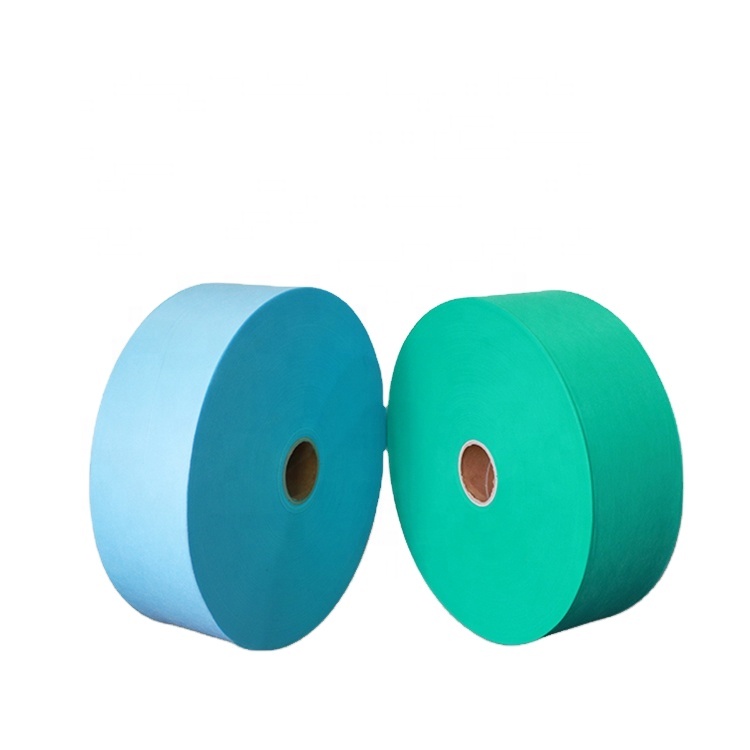

film and non-woven fabric

Third, in the production of coated non-woven fabrics, the technical cost of adding anti-aging agents after the plastic has melted is too high. Generally, the commonly used coated non-woven fabrics rarely add anti-aging agents, so that they will age faster under sunlight. . Since the PE film used in the peritoneal non-woven fabric has been added with an anti-aging agent before production, its anti-aging effect is also better than that of the coated non-woven fabric.In addition to sanitary protection products, film non-woven fabrics are also widely used in all aspects of life: environmentally friendly bags, shoes, clothing, jewelry, wine, shopping bags, home textiles, and high-end gift packaging with environmentally friendly materials.

written by: Ivy

Post time: Sep-07-2021