Let’s talk about the production process of disposable medical masks commonly used in the market and the disinfection process that we are most concerned about at present — how they are disinfected in the factory.

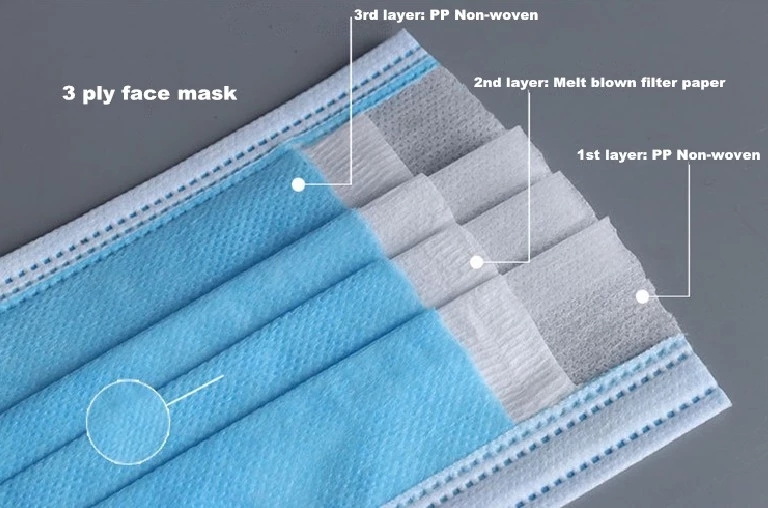

At least three layers

If you cut out the mask, you will see at least three layers of non-woven fabric, which is required by production regulations.

The middle layer is called “Meltblown Nonwoven”, which is made by Polypropylene in meltblown tech. As the core material of masks,it undertakes the primary task of defending against viruses, including Covid-19 virus.

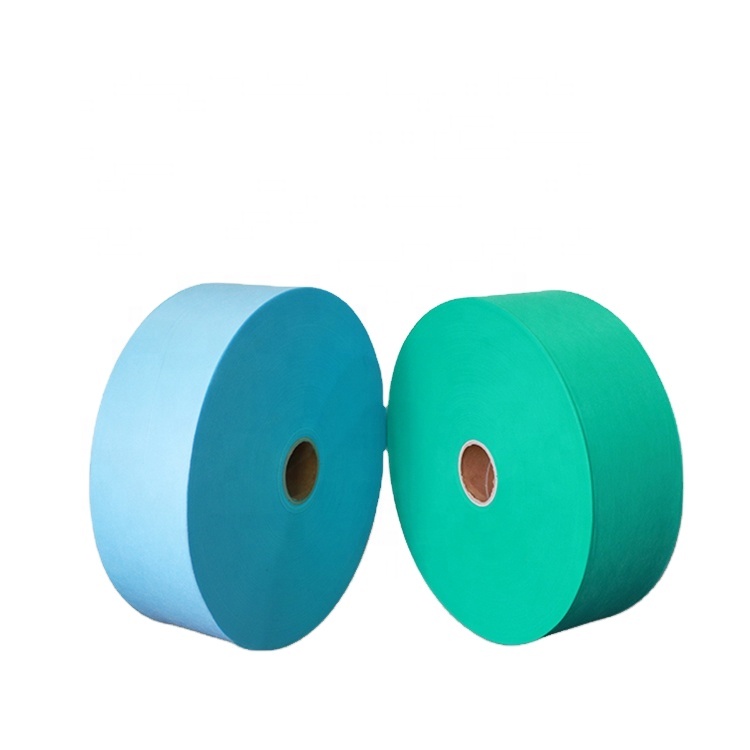

The outter and inner layer fabric is called “Spunbond Nonwoven”, which is also made by Polypropylene, in Spunbond tech although. This type fabric is widely used in so many areas, such as face mask, shopping bags, shoe interling, mattress etc.

During some periods in 2020, masks were extremely lack and some undesirable company produce and sell single-layer masks. It can not defense virus!

The Cotton Mask, could prevent big particle dust, keep warm in winter, yet they can not defense virous either.

Merge three layers

Such three layers of non-woven materials are superimposed together by a production machine like the one shown below.

Nose bridge

Nose bridge means the flexible wire on top of the mask. It is kneaded and fixed to the bridge of the nose when wearing, so that the mask can be tightly worn.

Without this structure, the mask won’t stick in face, and leave gap let air enter directly, affecting the protective effect.

The main part of the mask is the laminated structure shown in the picture below. When pulled out, it covers the mouth and nose completely, even big face.

The next step is to press the surface of the mask flat.

The cutting process

The single cutting and stitching of masks are mostly automatic processing. And different masks have slight manufacturing differences, some are sewn edge, some are directly hot pressing glue etc.

Fix the mounting Ear rope by hot pressing

Adhesive also needs to be used at the edge of the mask. As shown in the picture below, the mechanical claw delivers the lug rope, and the adhesive is hot pressed to fix the lug rope on the mask. In this way, a flat mask is finished.

Now there are different types of mask production line, and have been miniaturized, modular.

After purchase the machines, raw material such as spunbond fabric, ear bridge etc, a small mask manufacturing workshop can be set up in a few days. However, it should be noted that the production of medical masks generally requires inspection by the local government.

Disinfection sterilization

Fragile non-woven fabrics generally do not need high temperature disinfection, is the use of “ethylene oxide” colorless gas to kill bacteria, mold and fungi.

Ethylene oxide does not damage the sterilized articles and has strong penetration, so most of the articles that are not suitable for sterilization by general methods can be sterilized and sterilized by ethylene oxide.

An animation illustration was found. Batches of masks were sent to the disinfection room, and then ethylene oxide gas (yellow in the figure below for highlighting, but actually colorless) was applied to complete the disinfection process after reaching a certain concentration. The ethylene oxide is then diluted and pumped through air and nitrogen in the disinfection chamber several times until the residue of ethylene oxide on the surface of the mask is sufficient.

Ethylene oxide can be used to disinfect medical supplies such as medical bandages, sutures, surgical instruments and items that cannot tolerate high temperature disinfection.

Polypropylene spunbond non-woven fabric is a essential raw material when produce face mask. As 17+ years manufacturer, Henghua Nonwoven provide quality spunbond fabric in worldspread.

Delivery time: 7-10 days

Different colors available.

Click here or below picture to find details of medical spunbond nonwoven.

Welcome place order~

–Written by Mason Xue

Post time: Nov-19-2021