COVID-19 Response: Manufacturers and distributors that provide sources of COVID-19 medical supplies ico-arrow-default-right

Once a surgical mask was just a strip of cloth tied to the face of a doctor or nurse, it is now made of non-woven fabric made of polypropylene and other plastics for filtering and protection. According to the level of protection users need, they have many different styles and levels. Looking for more information about surgical masks to meet your medical purchasing needs? We created this guide to outline some of the basics about these masks and how they are made. If you are interested in learning more about how to manufacture respirators, protective clothing and other personal protective equipment, you can also visit our PPE manufacturing overview. You can also check our article on top cloth masks and surgical masks.

Surgical masks are designed to keep the operating room sterile and prevent bacteria in the wearer’s nose and mouth from contaminating the patient during the operation. Although they are becoming more and more popular among consumers during outbreaks such as the coronavirus, surgical masks are not designed to filter out viruses smaller than bacteria. For more information about which type of mask is safer for medical professionals dealing with diseases such as coronavirus, you can read our article on CDC-approved top suppliers.

It should be noted that recent reports from Healthline and CDC show that masks with valves or vents are more likely to spread infection. Masks will provide the wearer with the same protection as unventilated masks, but the valve will not prevent the virus from coming out, which will allow people who do not know they are infected to spread the virus to others. It is also important to note that masks without masks can also spread the virus.

Surgical masks are divided into four levels according to ASTM certification, depending on the level of protection they provide to the wearer:

It should be noted that surgical masks are not the same as surgical masks. Masks are used to block splashes or aerosols (such as moisture when sneezing), and they are loosely attached to the face. Respirators are used to filter airborne particles, such as viruses and bacteria, and form a seal around the nose and mouth. When a patient has a viral infection or particles, vapors or gases are present, a respirator should be used.

Surgical masks are also different from surgical masks. Surgical masks are used in clean environments in hospitals, including intensive care units and maternity wards, but they are not approved for use in sterile environments such as operating rooms.

As of November 2020, the CDC has revised its guidelines for the use of masks to allow hospitals and other medical centers to expand resources during periods of extreme demand. Their plan follows a series of steps for increasingly urgent situations from standard operations to crisis operations. Some emergency measures include:

Recently, ASTM has developed a set of standards for consumer-grade masks, in which class I masks can filter 20% of particles above 0.3 microns, and class II masks can filter 50% of particles above 0.3 microns. However, these are exclusively for consumer use, not medical use. As of the time of writing, the CDC has not updated its guidelines to address the issue that these masks (if any) can be used by medical personnel without proper PPE.

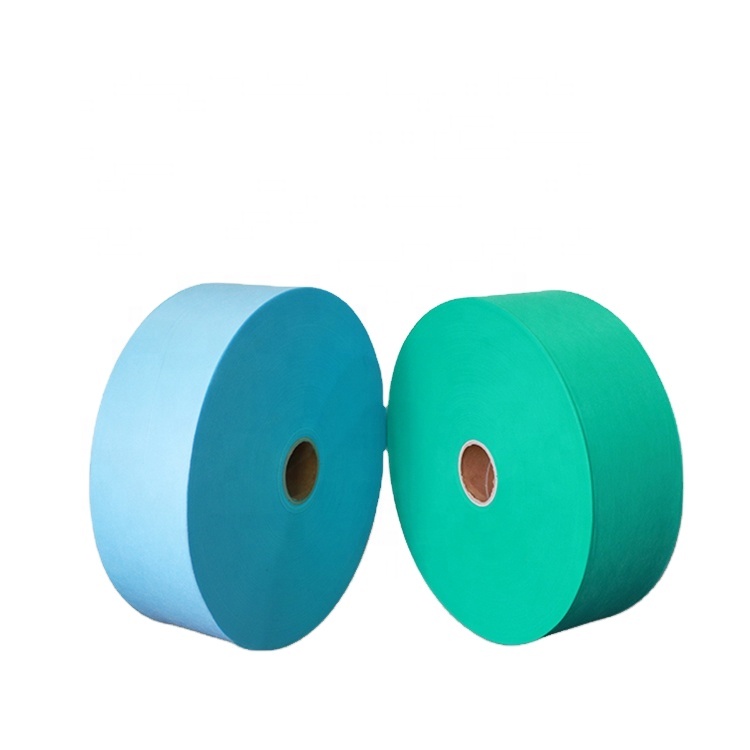

Surgical masks are made of non-woven fabrics, which have better bacteria filtration and breathability, and are less slippery than woven fabrics. The material most commonly used to make them is polypropylene, which has a density of 20 or 25 grams per square meter (gsm). Masks can also be made of polystyrene, polycarbonate, polyethylene or polyester.

The 20 gsm mask material is made using a spunbond process, which involves extruding molten plastic onto a conveyor belt. The material is extruded into a web, in which the strands adhere to each other as they cool. 25 gsm fabric is made by melt blown technology, which is a similar process in which plastic is extruded through a die with hundreds of small nozzles and blown into fine fibers by hot air, cooled again and placed on a conveyor belt上胶。 On glue. The diameter of these fibers is less than one micron.

Surgical masks consist of a multi-layer structure, generally a layer of non-woven fabric is covered on a layer of fabric. Due to its disposable nature, non-woven fabrics are cheaper and cleaner to manufacture and are made of three or four layers. These disposable masks are usually made of two filter layers, which can effectively filter out bacteria and other particles larger than 1 micron. However, the filtration level of a mask depends on the fiber, the manufacturing method, the structure of the fiber net and the cross-sectional shape of the fiber. Masks are manufactured on a machine line that assembles non-woven fabrics on spools, welds the layers together with ultrasound, and prints nose bands, earrings and other parts on the mask.

After the surgical mask is made, it must be tested to ensure its safety in various situations. They must pass five tests:

A clothing factory and other generic drug manufacturers may become a surgical mask manufacturer, but there are many challenges to overcome. This is not an overnight process, because the product must be approved by multiple agencies and organizations. Obstacles include:

Although there is a shortage of materials for surgical masks due to the continuing pandemic, open source models and instructions for masks made of more common materials have emerged on the Internet. Although these are for DIYers, they can also be used as a starting point for business models and production. We found three examples of mask patterns and provided links to purchasing categories on Thomasnet.com to help you get started.

Olsen mask: This mask is intended to be donated to hospitals, which will add a hair band and wax thread to better fit individual medical staff, and insert a 0.3 micron filter.

The Fu Mask: This website contains an instructional video on how to make this mask. This mode requires you to measure the circumference of the head.

Cloth mask pattern: Sew It Online’s mask includes the pattern design on the instructions. Once the user prints out the instructions, they can simply cut out the pattern and start working.

Now that we have outlined the types of surgical masks, how they are manufactured, and the details of the challenges faced by companies trying to enter the field, we hope this will enable you to source more efficiently. If you are ready to start screening suppliers, we invite you to check our supplier discovery page, which contains detailed information on more than 90 surgical mask suppliers.

The purpose of this document is to collect and present research on the manufacturing methods of surgical masks. Although we work hard to plan and create up-to-date information, please note that we cannot guarantee 100% accuracy. Please also note that Thomas does not provide, endorse or guarantee any third-party products, services or information. Thomas is not affiliated with the vendors on this page and is not responsible for their products and services. We are not responsible for the practices or content of their websites and apps.

Copyright © 2021 Thomas Publishing Company. all rights reserved. Please refer to the terms and conditions, privacy statement and California non-tracking notice. The website was last modified on June 29, 2021. Thomas Register® and Thomas Regional® are part of Thomasnet.com. Thomasnet is a registered trademark of Thomas Publishing Company.

Post time: Jun-29-2021